Boom and Platform Cabinets

Cabinet Systems

Snyder boom and platform cabinets are designed for delivery of railyard service and maintenance fluids, such as:

- Water, Potable and Non-Potable

- Lubrication Oil

- Journal Oil

- Compressor Oil

- Soap

- Compressed Air

- Toilet Chemicals

- Water Treatment

Boom and platform cabinets may be driven by water pressure to deliver potable or non-potable water, or combined with pumping systems to deliver other service fluids.

Standard Cabinet Features:

- Sturdy Snyder hose reel systems with automatic rewind motors

- Heated reel area to maintain proper fluid temperature

- Heated nozzle storage box for boom cabinets, with heavy-duty flaps to prevent freezing nozzles

- Heater Failure indicator light to notify railyard personnel of problems and prevent freezing

- START/STOP buttons for fluid flow

- Automatic rewind switches

- Pump Run indicator light

- Emergency shutoff valves

- Standard 210 nozzles (NOZZ-BRC-1035). for oil-dispensing units.

Optional Features

- Level wind mechanism to prevent hose binding

- Spring reels for platform cabinets

- Specialty reels/hoses/nozzles for chemical compatibility or other custom requirements

- Special plumbing for potable water systems

- Customized lengths/heights for boom cabinet arms.

- Custom units to deliver multiple fluids from a single cabinet

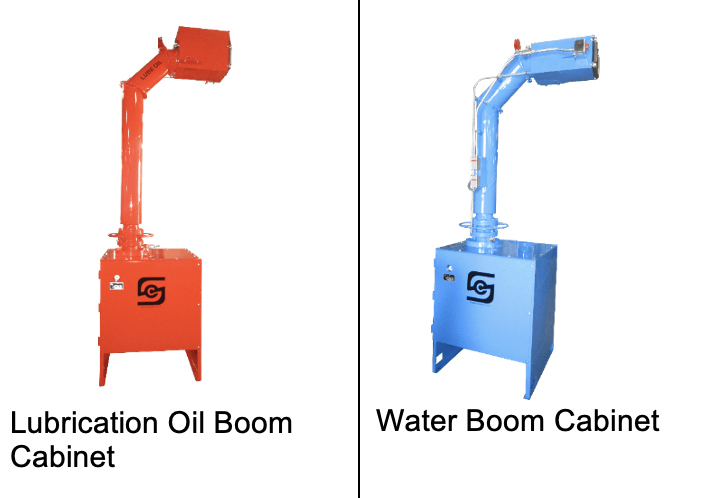

Boom Cabinets

Boom cabinets are designed to deliver service fluids at cab level or where elevated walkways are present. The boom arm rotates to serve parallel tracks on either side of the boom. Typical rotation is 270-300 degrees, other rotations are available upon request.

Heated nozzle boxes at the end of the boom arm provide a safe storage environment.

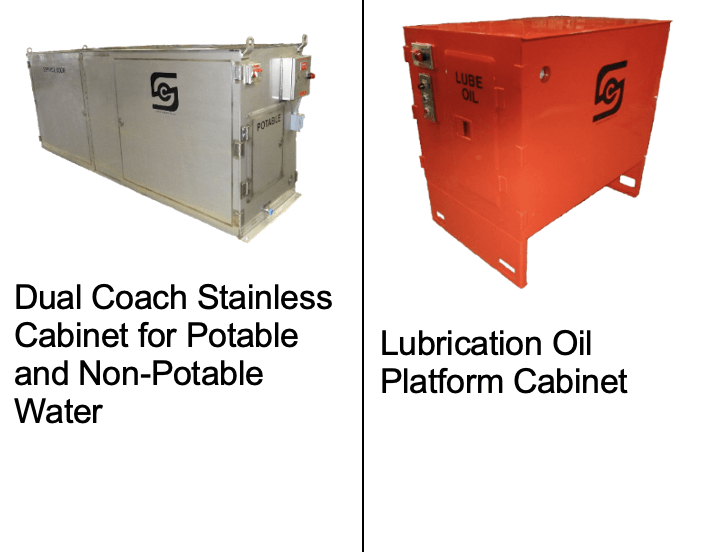

Platform Cabinets

Platform cabinets are designed to deliver service fluids at ground level.

Latching doors on the end of the cabinet allow access to the nozzle and hose assembly and provide a safe storage area for nozzles when the cabinet is not in use.

Hinged maintenance doors on either side of the cabinet allow for easy servicing and routine maintenance.

Stainless-steel cabinets are available for water and treated water applications.

Standard Water Platform Cabinet Drawing (544-40-PC-W-W.E - SALES.pdf)

Need a non-standard cabinet? Snyder offers custom cabinet design and a variety of specialty cabinets options. For examples, learn more here.

Common Questions

See some common questions and answers below, or call us at 417-725-4067