Remanufactured Air Dryers

ABOUT

ABOUT

Snyder Equipment offers remanufactured Graham White air dryers. We rebuild both 975 Twin Tower and 994-500 series air dryers. Dryers may be supplied in memory or non memory mode as required.

Subassemblies and components are replaced by new or re-qualified parts to meet OEM dimensions and tolerances. Re-qualified parts are thoroughly cleaned, inspected for defects, and measured to OEM specifications. Parts that do not meet specifications are either reconditioned or replaced.

All rebuilt air dryers are 100% functionally tested prior to shipment to meet drying conditions and proper cycling.

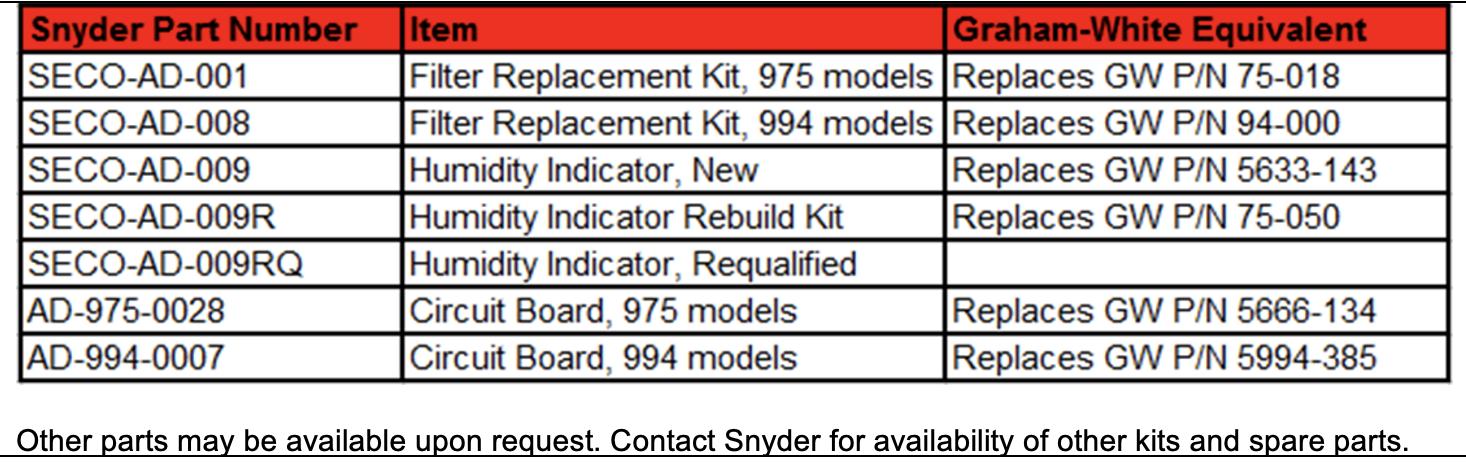

In addition to remanufacturing air dryers, we also offer field service kits and certain replacement parts. See the Field Maintenance Kit section below.

How to order Remanufactured Air Dryers

Snyder operates on a UTEX program, requiring a core to be submitted for teardown. Customers supply a purchase order along with a suitable core for the model that is ordered. A core charge may be assessed if certain critical parts are unusable.

In general, Snyder does not sell remanufactured air dryers without core, but there can be exceptions. Contact Snyder to discuss any special requests

FAQs

Got a question? We’re here to help.