Fuel Cranes

Snyder 104-HP-1 and 104-HP-2 Fuel Cranes

For efficient transfer from fuel pumping systems to fueling nozzles.

Multiple swivels allow fuelers to easily reach any spot within the track radius for each model. After fueling is complete, hydraulic cylinders return the crane to the resting position shown at right.

Maximum Reach: 15 ft for HP1 and 23.5 ft for HP2

Tensions are factory set under a full fueling load to make the crane ergonomically friendly while keeping an efficient return time to resting position.

Standard HP-1 Fuel Crane Drawing (104-HP-1.E)

Standard HP-2 Fuel Crane Drawing (104-HP-2.F)

HP-1 Spacing Example (104-HP-1 22)

HP-2-Spacing Example (104-HP-2 32)

Fuel Crane and Boom Cabinet Layout Example (HP12FCTL)

Fuel crane systems may be customized to fit individual site needs. Options include:

- Custom inlet piping configurations for above-grade or below-grade connections

- Integrated control with pumping systems (START/STOP buttons)

- Addition of meters/counters/ticket printers

- Flex hose assemblies and/or strainers

- Dual counterbalances (“cactus” cranes)

- External filter vessels

- Extended reach radius (HP3 cranes)

- Integration with fuel management systems

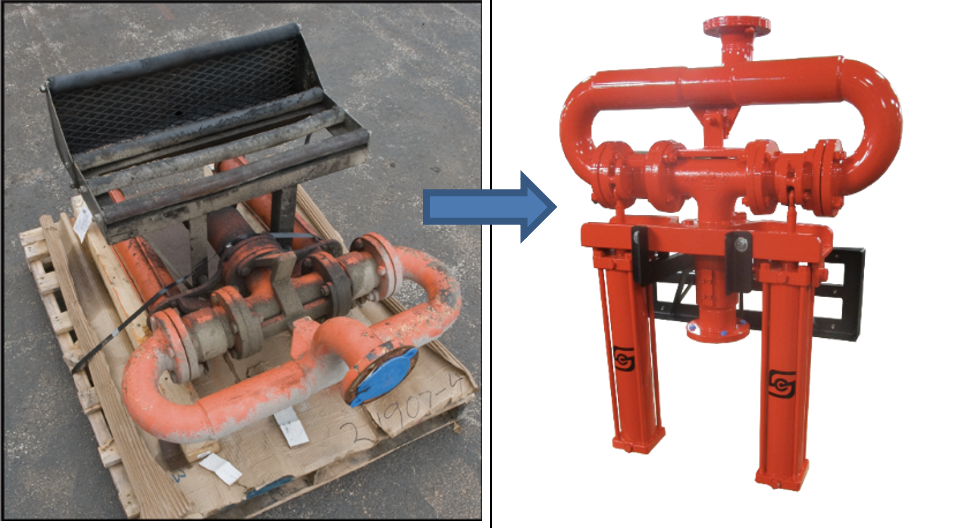

Re-qualified Fuel Cranes

Snyder offers a re-qualification program for fuel crane counterbalances.

- Incoming counterbalances are disassembled and thoroughly cleaned and sandblasted.

- All parts are measured and inspected/crack checked as required.

- Counterbalances are reassembled using re-qualified hydraulic cylinders

- Counterbalances are leak tested and adjusted for standard field conditions

- Counterbalances are primed/painted and prepared for shipment.

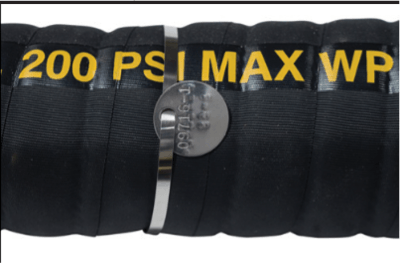

DROP HOSES

Drop hoses provide flexibility so fuelers can easily connect nozzles to locomotive tank adapters.

Snyder’s standard 200 PSI drop hoses provide improved ergonomics with excellent degradation resistance. Crimped ends provide a 4:1 safety ratio.

Standard drop hoses come with flanged upper connections. Older cranes with drop pipes may require shorter hoses with Kamlock connections on both ends.

Drop hoses may be requalified by Snyder if the existing couplings can be reused.

How to Specify Drop Hoses

Specify new (FCNDH) or requalified (FCRDH).* The remaining numbers follow a X-Y-ZZZ format.

X: Crane Type

1 = HP1

2 = HP2

3 = HP3

Y: End Connections

1: Kamlock to Kamlock, use only with drop pipes

2: Kamlock to Flange, full length hose

Z: Length of Hose Assembly in Inches

Use the longer hose if attached nozzles have 30-degree swivel inlets.