Auxiliary Fueling Equipment

Nozzle Tester

The Snyder Nozzle Tester allows for service track testing of nozzles under certain conditions. It closes off the vent hose connection and replaces it with a separate open hose and ball valve.

Once the air supply from the vent hose is cut off by closing the ball valve, the nozzle will shut off as long as the fuel supply covers the tank inlet and the tank adaptor is properly installed.

Learn more here

(NOZZ-BRC-1024)

CAUTION: The ball valve and hose must be installed between the 9 o’clock and 3 o’clock position as shown. Improper installation may result in a fuel spill.

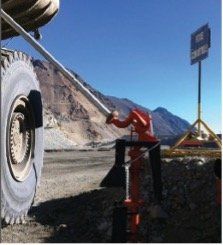

Nozzle Ring Tester

Worn locking rings can prevent nozzles from sealing properly, leading to automatic shutoff failure and potential spills.

The Snyder 565-TR Nozzle Ring Tester is designed to test the locking ring on nozzles independently from the fueling process.

Mount the ring tester securely prior to testing, insert the nozzle to be tested, and tighten the locking ring until it cannot be turned further by hand.. If the lobes stay within the green range on the adapter surface, the locking rings are good.

NOTE: Install a fresh FR65 gasket in the nozzle ring prior to testing. Worn or missing gaskets may lead to a false reading.

Learn more here (NOZZ-BRC-1046)

Mining Equipment

Snyder offers specialized fueling systems for mining operations, along with specialty cabinets and other equipment built to MSHA standards.