Capabilities

Pre-Fab Equipment

•Trumpf® 4000W Sheet Laser – 5x10 Shuttle Table with Roto Las Tube Laser built-in to unit.

•Amada® 357 Queen Turret Punch- 58 station 3”

•1-Haeger® 618 Plus Automatic Hardware Inserter Machine

•1-Almco® Drum Tumbler 2 Door 48” x 72

•1-Clausing® 12” Drill Press

•1-Wysong® 72” Mechanical Plate Shears

•1-Cincinnati 12’-0 Mechanical Plate Shears

•2- Bead Rolling Machines

•1- Toggle Lock Press 30T Air/Hydraulic

•1- Seam Locking Press 50T Mechanical

•1- Seam Stacking Machine Pneumatic

•4- Punch Presses 30 thru 75 ton Mechanical

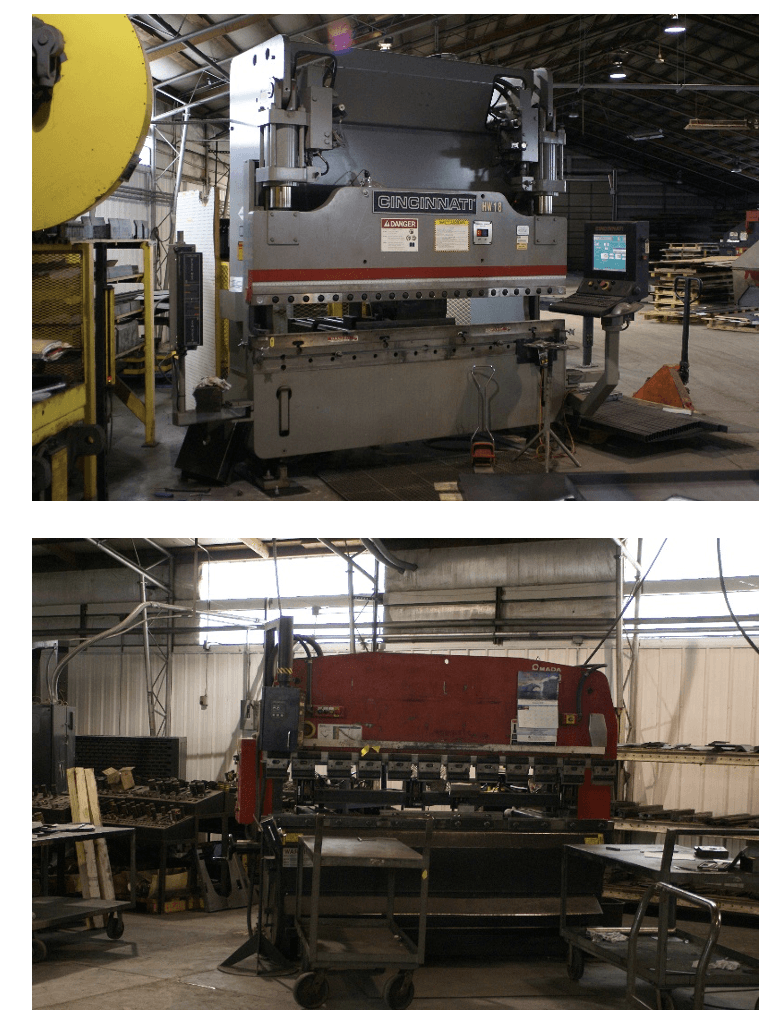

•2- Amada® RG80 Precision Press Brakes

•1- HTC® 250 Ton x 12’-0 Hydraulic Press Brake

•1- Cincinnati 90 Ton x 10’-0 Precision Press Brake

•1- Montgomery 5’-0 Initial Pinch Plate Roll

•1- Hydro Press 500T 10” Dual Acting Ram/Spud

•2- Hydro Press 100T 10” Dual Acting Ram/Spud

•1- Hydro Press 500T 8” Dual Acting Ram/Spud

•1- De Coiling Machine, 3000# x 20”

•1- Government Seam Folding Machine 48” x 18ga

Welding Equipment

•3-Miller® Delta Weld 302 w/ 22A Single Head Feeders Portable

•2-Miller® Delta Weld 355 w/ 22A Dual Head Feeders Portable Jib Mounts 35’ reach

•2- Miller® Synchrowave 250 Tig Welders water cooled

•1- Miller® Dynasty 200 Tig Welder air cooled

•1- Gullco Moggy Welding Tractor-Straight Line Continuous/Intermittent Welding

•1- 5’-0 x 25’-0 Cast Iron Acorn Fit-up Table

Painting Equipment

•GAT® (General Automatic Transfer) Powder Coating System- 540’ Continuous Line with 4-Stage Detergent Wash and Phosphate Coating, LP fired Curing Oven

•Weight Capacity= 200 Lbs. / Trolley Located on 24” Centers

•Size Capacity= 30”D x 72”L x 72”H

•Graco® 3100 PSI Portable Airless Sprayer

•Sand and Grit Blasting is subcontracted on and offsite

Material Handling and Packaging Capabilities

Engineering Design and Support

•AutoCAD Inventor® software

•Sheet metal/plate layout from customer-supplied details

•Support Functions at Nixa Facility

- File conversion capabilities to convert alternate customer file formats (.idw, .stp) to .dxf

- Drawing/design assistance as required

- 3D modeling and layout capabilities for prototyping

Excelling Worldwide Since 1936

We are available via fax, email or telephone

Call

417-725-4067

All Rights Reserved | Snyder Equipment, A Division of New York Air Brake LLC

4654 W Junction St, Springfield, MO 65802 | Ph. (417) 725-4067 Fax (417) 725-4846