Remanufactured Air Dryers

ABOUT

How to order Remanufactured Air Dryers

FAQs

- What locomotive air dryer models does Snyder rebuild?

We rebuild Graham White model 975 twin tower and 994-500 series dryers, both memory and non-memory models. We do not currently rebuild 994-600 series and above, or older Wabtec Vaporid model dryers. We are preparing for future rebuilds of model LD-1000 air dryers for our parent company, New York Air Brake. Contact Snyder for any questions on our capabilites for less common models.

- Do you offer upgrades?

We offer transition of non-memory to memory models and vice versa. Generally, we do not offer other upgrades.

- Does Snyder operate as a repair and return?

Most repairs are done under UTEX terms – you send us a core air dryer and we send you an equivalent air dryer in return. In some cases Snyder will operate under repair and return for the same air dryer you send in. Terms must be clearly outlined before a repair and return P.O. is issued.

- What is a core charge?

Core charges apply when major components of the supplied core are missing or unusable and considered to be scrap.

Major components for 975 model air dryers are:

Dryer bodies

Bottom caps/Sump caps

Purge/Drain valve assemblies

Check valve assemblies

Electrical housings

Dryer bodies that are damaged beyond repair initiate a core charge. A core charge also applies when any two of the other components that are missing/damaged beyond repair.

Major components for 994 air dryers are:

Upper/lower manifolds

Electrical housings

Valve assemblies/blocks

A core charge will apply when any of these components are missing or damaged beyond repair.

- What work is performed on a remanufactured air dryer?

Select the link below for the Statement of Work and specification for your air dryer.

Graham-White models (AIRD-INFO-1000).

New York Air Brake models (not yet available).

- What is Snyder’s warranty on air dryers?

Snyder offers a one-year warranty on remanufactured air dryers.

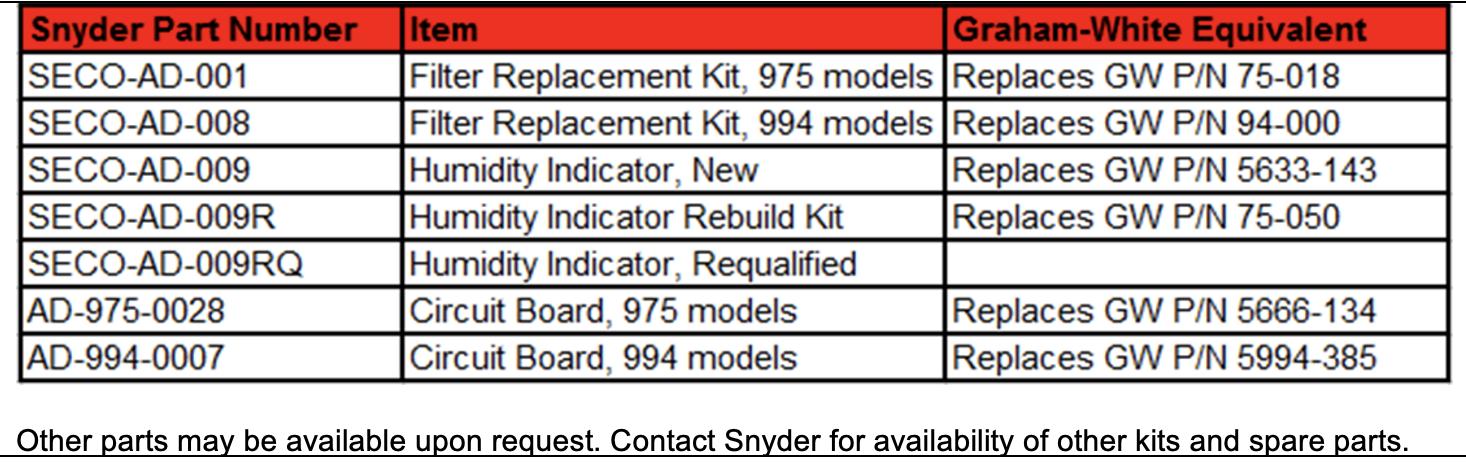

- Do you sell replacement parts?

We supply common field replacement kits (coalescer filters and corresponding seals, and humidity indicators) for 975 and 994 models, as well as replacement circuit boards and various o-rings/seals. Contact us if you have a question on a particular component.

- Air dryers fail quickly on one particular locomotive. Why?

Air dryers are made to remove the water from saturated air, assuming that liqud water has been removed by the upstream MR1 reservoir. They can’t handle much incoming liquid water before the desiccant becomes swamped and unable to function. Check the MR1 drain valve to verify that it is properly removing condensate from the tank and not passing it through to the air dryer.

Brown humidity indicators show oil contamination from the compressor, which will coat the desiccant and cause it to fail.

Also make sure that locomotive wiring matches the dryer setting. Memory dryers will not work properly if installed in locomotives wired for non-memory operation, and vice versa.

- My humiidty indicator isn’t blue anymore. What does this mean?

A lavender color means that the dryer has excess water but can corrrect itself over time if it doesn’t see significant liquid water. Other colors indicate service is required. White means the dryer has been swamped with excess liquid water and can’t recover. Brown indicators show the presence of oil. Orange and green indicators also show the presence of contaminants.

Excelling Worldwide Since 1936

We are available via fax, email or telephone

Call

417-725-4067

All Rights Reserved | Snyder Equipment, A Division of New York Air Brake LLC

4654 W Junction St, Springfield, MO 65802 | Ph. (417) 725-4067 Fax (417) 725-4846