Tote and Pump Cabinets

For Efficient Delivery to Service Track Equipment

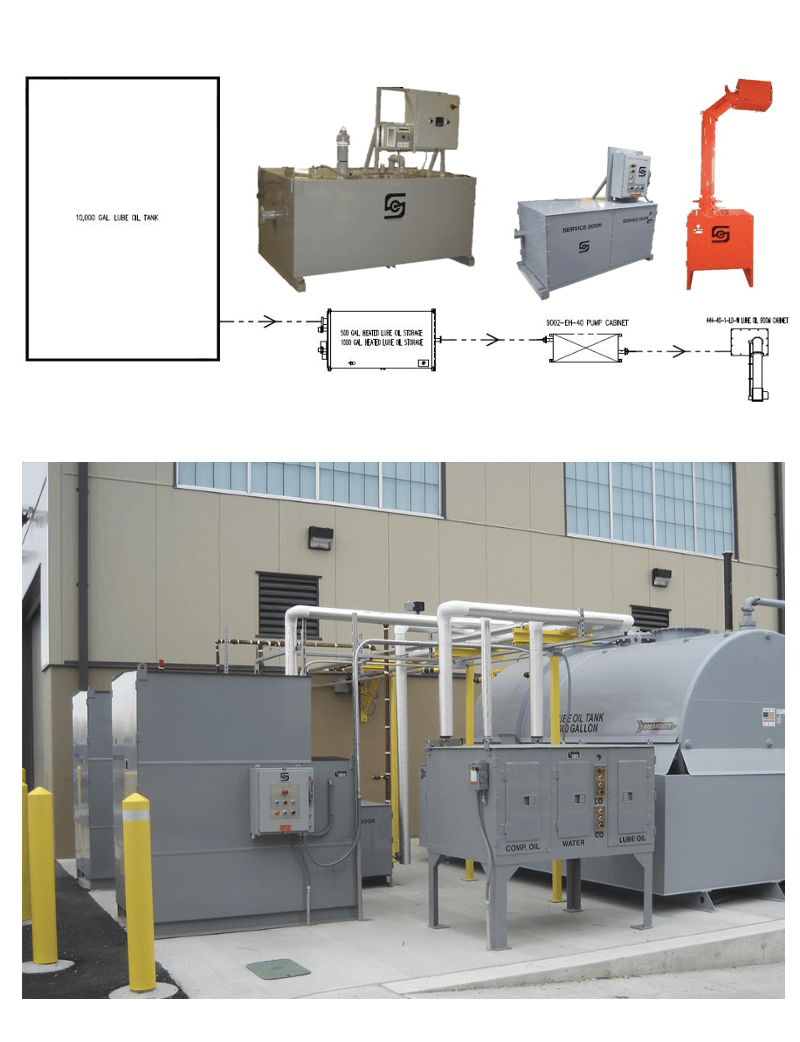

Pump Cabinets

Snyder pump cabinets are heated cabinets designed to pump service fluids to boom cabinets while maintaining the proper pumping temperature and fluid viscosity. They are typically used in lubrication oil systems but can be used for most service fluids.

Pump cabinets may also be combined with intermediate heat and storage cabinets to prevent pumping problems from distant bulk tanks.

Tote Cabinets

Snyder tote cabinets are combined reservoir and pumping systems, often used in situations where a large reservoir is uneconomical or impractical. Typical uses include compressor oil, journal oil, lubrication oil, toilet chemicals, fuel additives, water treatment, and cleaning chemicals.

Tote cabinets are portable and simple to install, allowing flexibility in service track layout. All tote cabinets feature 110% containment sumps to prevent external spills.

Customized Tote Cabinets

Tote cabinets can be customized with internal hose reels with access doors or attached booms to make a portable and fully self-contained fluid storage, pumping, and delivery system.

- Contact Snyder for assistance in designing a specialty pump/tote system for your application.

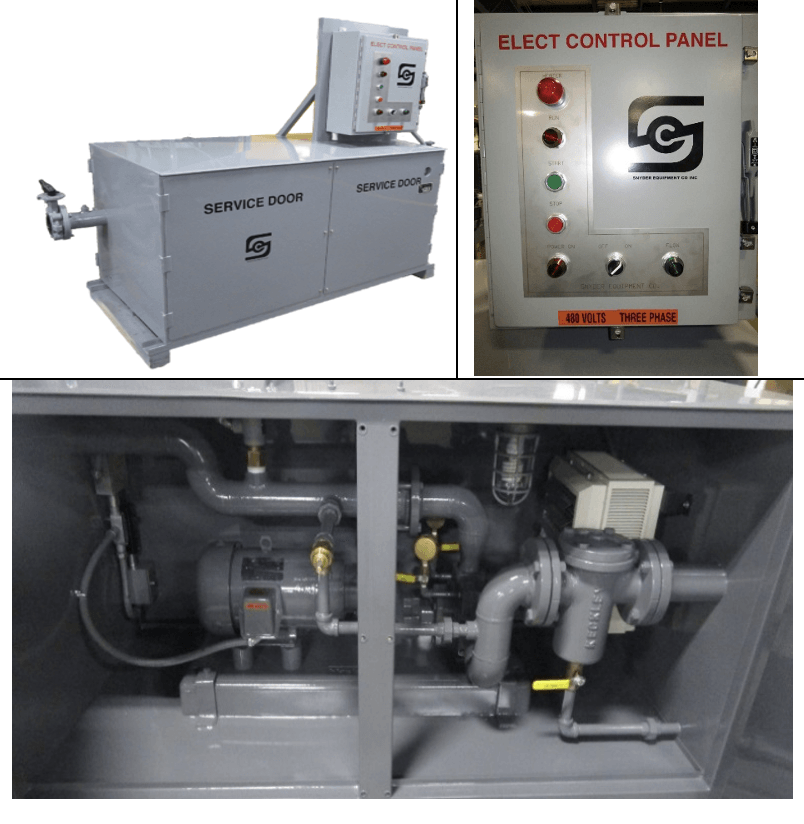

Standard Pump Cabinet Features

- 40 GPM capability

- Internal bypass loop to regulate flow and pressure and extend pump life

- 3000W thermostatically controlled heater

- Large access doors to simplify maintenance

- Control panel with START/STOP push buttons and indicator lights for heater falure, power, and flow.

- Check valve to prevent backflow

- Inline strainer

- Built-in worklight

- External inlet/outlet butterfly valves

Other features such as a cold start interlock may be added upon request. Contact Snyder for help with a customized design.

Standard Tote Cabinet Features

Standard Tote Cabinet Features:

- 110% containment sump to prevent external spills

- GPM capability matched to fluid requirements

- Internal bypass loop to regulate flow and pressure and extend pump life

- 3000W thermostatically controlled heater

- Large access doors to simplify maintenance and tote change outs

- Control panel with START/STOP push buttons and indicator lights for heater failure, power, and flow

- Check valve to prevent backflow

- Inline strainer

- Built-in worklight

Other features such as an on-demand configuration may be added upon request. Contact Snyder for help with a customized design.

Standard Compressor Oil Tote Drawing (SECO-TCAB-CA.F)

Standard Journal Oil Tote Drawing (SECO-TCAB-JA.F )