Derail Boxes

Derail Boxes

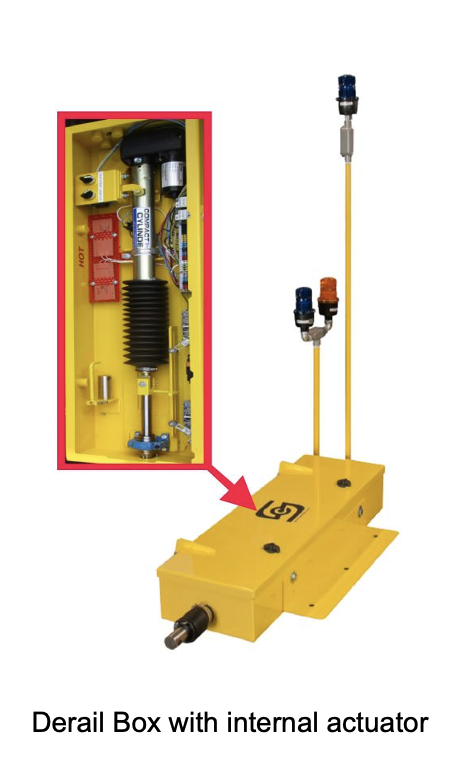

Derail boxes are emergency systems that keep locomotives off restricted tracks.

When activated, an actuator pushes a rod forward, forcing a derailer at the end of the rod over the top of the rail. Warning lights indicate the derail status.

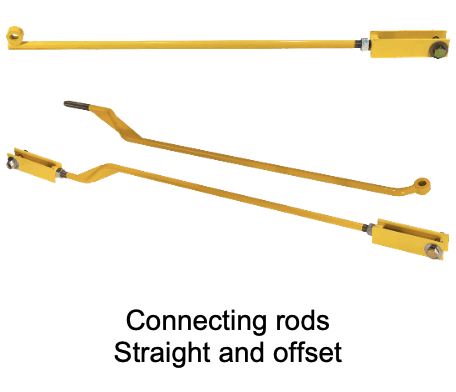

Derail boxes are sealed and may be flush mounted using straight rods or raised using offset rods.

Derail box systems may be hardwired or wirelessly controlled. Controls can be supplied as an external panel or as part of a touchscreen system.