Water Treatment

Locomotive Cooling System Protection

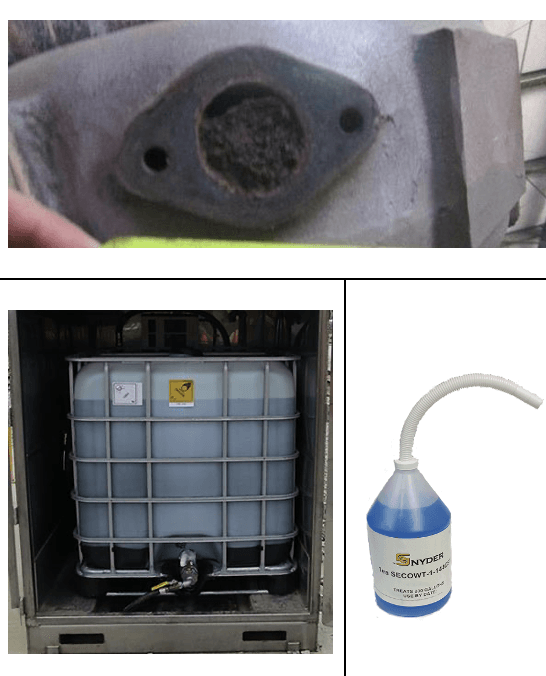

Without suitable treatment, locomotive radiator systems can quickly corrode. Loose rust can cause clogs and restricted flow throughout the cooling system, causing overheating. Severe corrosion can cause leaks leading to catastrophic system failure.

Snyder’s nitrite-borate liquid water treatment systems are designed to maintain a constant ratio of treatment chemical to water, eliminating the need for calculations or guesswork when topping off cooling systems.

Liquid systems avoid potential problems of undissolved solids from powdered concentrates and soluble bags.

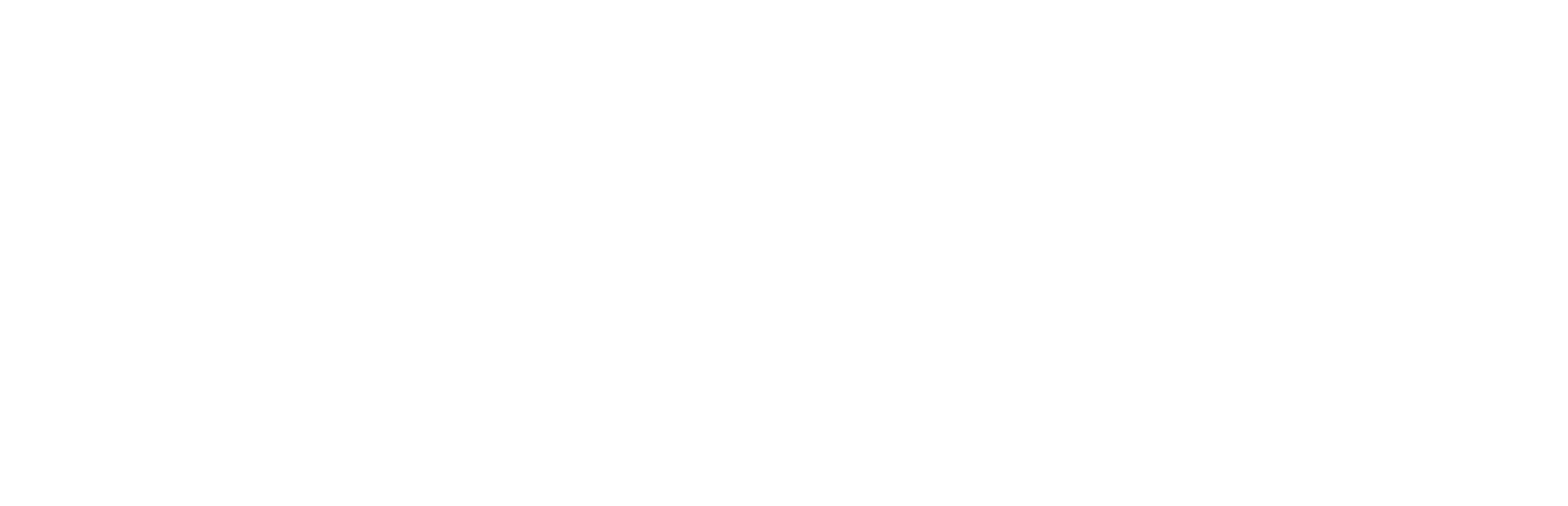

The liquid is available in gallon jugs for complete draining and refilling, or in 240/330 gallon totes to supply delivery systems. The label on gallon jugs shows the proper amount of concentrate to refill many locomotive types based on their radiatior capacity.

Gallon jugs are supplied with a spout for easy spill-free filling.

The concentrate contains dye (typically red or blue) to verify the presence of treatment.

Delivery Systems

Water treatment delivery systems use an injection mixer to provide a constant water treatment ratio regardless of water flow rate. The ratio is set at Snyder to provide the proper treatment level.

There are three styles of delivery system:

- Cabinets – Enclosed and heated systems for service track applications

- Shop systems – Streamlined units for shops and controlled environment facilities

- Portable Carts – 25 gallon concentrate capacity, perfect for smaller facilities or hard-to-reach service areas.

Maintenance Kits

Mixers wear out after approximately one year of use and require field replacement. Snyder supplies pre-calibrated replacement mixer kits with pre-installed half unions to allow simple replacement.

PMP SD302.5 K1 kits are for older units with one union and one hose connection.

PMP SD302.5 K2 kits are for newer units with two unions.

Snyder recommends nitrite titration to verify treatment concentration. We offer nitrite titration kits (SECO-TW-NTK) to verify output and determine when a mixer needs replacement or maintenance.

Learn more about Snyder Water Treatment options here

Water Treatment Systems Brochure (WTH-BRC-1006)

How to adjust water treatment mixers (WT-INFO-1000)

SDS (SDS sheets)